The Contribution of the BPM in the Manufacturing Industry

BPM tools are more relevant than ever and could well take on as important a role as ERP in the digital transformation process of organizations. As a true complement to ERP, BPM has a structuring effect, insofar as it allows business processes, the pillars of a company’s activity, to be modeled. Is BPM adapted to the industrial sector, why and how to choose a BPM tool and especially what benefits can be expected? This is what we propose to you to see in this article.

What is a BPM?

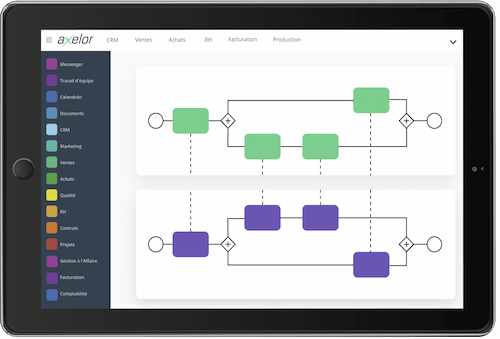

BPM stands for “Business Project Management”, the idea being to use a software tool to make the business processes on which a company is based, more efficient. A BPM tool is therefore based on 4 pillars: the graphic modeling of processes, their automation, the monitoring of workflows, and a focus on continuous improvement. The BPM is based on an international standard, the BPMN «Business Process Model and Notation» which provides a unified and simplified modeling language used for the process description.

In addition to the BPMN standard, there is the DMN “Decision Model and Notation” standard, which offers a standardized language, this time not for the processes but for the business rules and decisions that govern the processes.

Is the BPM suitable for industry?

The industrial sector is also confronted with the problem of process management in the same way as service or trading companies, for example. The notable difference in the industrial sector is that a large part of the activity is based on machines, and not only on human tasks. This is not an obstacle to the use of a BPM tool. On the contrary, BPM tools, beyond automating processes, also offer great connectivity to the software and machines that underlie an industrial activity.

Why a BPM in the manufacturing industry?

Companies in the industrial sector face increasingly high competition. Digitalization is therefore necessary: in order to remain competitive, it’s important to have tools that increase flexibility and productivity. Digitalization is beneficial at all levels of industrial companies’ activity. Allowing the different services to understand each other through the BPM tool. Thus, a BPM would allow to orchestrate both human and machine processes, allowing to have a global coherence on any type of task needed to be accomplished. The BPM tool can also improve the customer experience, for example, by providing dedicated interfaces. Another crucial aspect is reporting: to remain competitive, an industrial company must be able to consult its indicators at any time in order to optimize its commercial strategy.

How to complete a BPM project?

A few points to consider in order to complete this strategic project:

- Identify and prioritize your processes

- Model your processes using BPMN

- Rally your teams around the project

- Get business and technical players to work together

- Identify quantifiable and achievable areas for improvement.

The choice of solution is also important. Make sure you choose a solution that offers a high level of functionality as standard. Ideally, a BPM should already be equipped with the main processes found in every industry (management of bills of materials, routings, MO, S&OP, PP, etc.), so as to save time when implementing company-specific processes, without having to recreate standard processes.

Opt for an ergonomic, easy-to-use solution, which will facilitate change management. Scalability is the key to choosing your future tool. So give preference to Low-Code tools – such as Low-code BPM – which use process engines and intuitive, graphical user screen creation. In this way, you retain control over the scalability of your tool: make adaptations in real time, without any external technical intermediaries or lines of code.

A BPM solution must be at the service of your organization’s continuous improvement, while saving you time and money!

The benefits of BPM in the manufacturing industry

The reactivity and agility provided by a BPM tool are more than beneficial to industrial companies, who will be able to see a positive and concrete impact, since such a tool makes it possible, among other things, to:

- Digitize processes to ensure their continuity

- Improve reactivity in the event of an anomaly

- Improve team cohesion

- Optimize document and knowledge sharing

- Contribute to quality policy and continuous improvement

- Provide a common database and collaborative application

The industrial sector relies on structured processes, teamwork, and extensive quality monitoring, so the BPM tool is essential from both an operational and a human point of view.

Now, more than ever, is the time for digitalization. Companies are in the throes of change, so they need to equip themselves with flexible tools. Your business processes are your DNA, and above all an extraordinary lever for growth. Relying on a BPM tool ensures that you have full control over your know-how, and that your organization has a long-term future. BPM also enables teams to work together, improving responsiveness and customer satisfaction. To stay competitive in an increasingly competitive environment, you need to be able to react quickly. BPM is your ally, so take the plunge!